FTF and FTRTB are two different malfunctions that have been lumped into one. Failure to feed means that it never gets to the chamber. If the round enters the chamber at all…even if just barely…it’s a failure to go to or return to battery.

Failure to feed is usually caused by either the feed ramp angle…too steep…or the magazine…nose-diving the round into the feed ramp and refusing to go further. In this one, polishing the feed ramp rarely ever changes anything. The feed ramp angle is critical. If it’s wrong, it’s wrong.

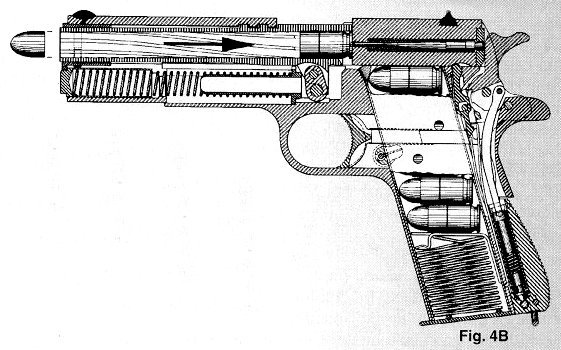

Failure to go to battery is usually caused by feed ramp angle not being steep enough and sending the bullet nose straight into the barrel ramp…pushing the barrel forward and up into the slide too early. The front corners of the barrel lugs crash into the rear corners of the slide lugs…and it all comes to a screeching halt. This one is known as the “Three Point Jam” and it’s a doozy.

The slide very often can’t be pushed or bumped to battery…but not always. What always does happen is a case with a gouge about 1/8th inch long and about 1/8th inch below the mouth…and a definite “Ka-Chunk” sound and feel if the round gets past the jam and feeds. For the ones that do manage to chamber, the sound is present on the first round or two, and often absent on subsequent rounds. Long-term damage to the barrel lug corners also shows up.

FTRTB can also be caused by the extractor, and in a pistol that’s right on the edge…the extractor can push it over the edge into a full 3-Point. Extractor-related failures with no ka-chunk and no case damage is known as “Stem Bind” though that term is a little misleading. All tilt-barrel locked breech pistols operate with some degree of stem bind. When it causes a problem, it’s technically called “Excessive Stem Bind.”

It’s usually assumed that excessive stem bind is the fault of excessive extractor tension, but that’s rarely the case. If all is within spec mechanically, the pistol will tolerate a surprising amount of tension without causing a problem. Here, the amount of extractor deflection is most often at the root of the problem.

The amount of the tensioning wall protruding into the breechface feedway determines deflection. I like to see .010-.012 inch with a maximum of .015 inch, or about a 64th. Excessive deflection can be caused by the extractor channel being bored on an angle…or too large…or the front locating pad of the extractor being too small. The good news is that it’s pretty simple to adjust. The bad news is that it requires a fairly expensive safe-sided file to do it correctly. I use a rail file with two safe sides and one safe edge. It fits perfectly and it’s easy to keep the tensioning wall square with just a little care.

Cut the wall with the cutting edge…checking the deflection with each cut on the first attempt. When it’s about right, you may have to remove a little from the hook to keep it from bottoming in the extractor groove. The tip to wall distance should be .035-.038 inch with .032 as an absolute minimum. Then, as SOP I like to use the same file to create a small 45 degree bevel on the bottom corner of the wall. That creates a camming surface that opens the extractor more gradually, and it lets the rim get deeper into the extractor before applying full tension. Then, lightly radius the bottom and top corners of the hook, so that looking at it from the front of the gun…it takes on the shape of a D.

Back to the frame ramp angle and the accursed 3-Point Jam.

The feed ramp angle is 31-31.5 degrees with no minus tolerance…which makes it pretty critical. If that angle is right, the gun will usually run fine unless the barrel ramp angle is way too steep. With the barrel ramp…aka “throat”…there’s more wiggle room as long as the bottom edge of the barrel ramp is sitting slightly forward of the top of the feed ramp…and even if that gap isn’t there…many pistols with the optimum feed ramp will feed hardball without a hitch.

The thing to keep in mind is that the barrel ramp isn’t an extension of the feed ramp, and it’s not a bullet guide. It’s a clearance. If the bullet nose glances off the feed ramp, and over the top corner of the barrel ramp without touching it…or at most, lightly brushing it…the gun will feed like green grease through a sick goose with about any reasonable bullet shape you can throw at it.

I have a 1919 production “Black Army Colt” that can’t tell the difference between hardball and hollowpoints…including the Speer Flying Ashtray…and Hensley & Gibbs #68 cast SEC…and it’ll feed’em from the original “Hardball” magazines. And more…my Remington Rand…The Union Switch Twins…two WW2-era USGI Colts…and a 1925 production Commercial Government Model will do it, too…and none of them have been altered in any way.

And that’s where Dremel Dan’s Double Throwdown Ramp’n’Throat job brings the tears of regret. I’ll get into that in another thread. For now, all I’ll say is…Best leave the feed ramp alone, pardner.

Logged

Logged

the only problem with 1911 not reliable., is other people making them and thinking they know how to better make them than colt. if made properly to the original specs from colt and browning, they will work always period.

now ever tom dick and kimber make them and make them cheap and change this and that. they dont work, and the ignorant blame the 1911, not the makers of the unreliable 1911s

Exactly correct.

Amen

I’ve had trouble with my Colt Lightweight Commander out of the box. I’m having FTRTB issues where the round nosedives up typically on the last round of the mag. I even sent the pistol into Colt to be repaired. I think it did work for a while after they sent it back. I believe they polished the extractor. Then after a while I started having the exact same issue. I just ordered a Vickers Duty mag from Wilson combat. I hope that will get her to working again. I had such high hopes and expectations that she would function flawlessly. Especially after all of the hype. I’m extremely frustrated and disappointed. I still love Colt and plan to purchase another 1911 as a way of giving them another chance, but if I have issues with my next purchase then Colt will no longer have me as a 1911 customer. I’ll probably still buy their AR-15’s though. Love both of my Colt AR’s

Did the Wilson mags help the feeding and stoppages! I’ve got a 5″ Oriskany Arms 1911 that is ftf ing. The parts appear beautifully made, so hoping it’s a magazine problem..from Wyoming USA 🇺🇸 👋🤠

I bought a Springfield 1911 in 1999. It didn’t feed anything reliably. I got a FTRTB, or nose dive into the bottom of the feed ramp every other mag at best, and sometimes more than once per mag. After running a couple of hundred rounds through it, thinking it would “break in”, I put it on the shelf, disappointed that it didn’t function. Then my dad bought a few 1911s; A Kimber, and a few others that were a few hundred dollars more expensive than my basic Springfield, and they all ran like champs. Their slides racked like butter, and my Springfield was sticky, and clunky feeling. I’m just now addressing the issues with this gun, and I don’t fully understand the verbal descriptions in the two articles here. I have some no name magazines, and a Wilson Combat mag, and only one of the no name mags works decently. I’m looking to learn how to tune the mags, and fully understand the extractor dimensions that were mentioned above. I manually bent the extractor to lighten the tension, and filed the sharp edges with tiny files, which didn’t seem to help, though it barely held the bullet when I held the gun upside down. I appreciate the knowledge sharing.