Recoil and the 1911

Recoil…action and reaction…is really no more than acceleration brought about by a force applied. The force generated by burning powder and expanding gases create pressure and directional movement of the gases. A force vector. These forces provide acceleration of both bullet and breechblock…which is essentially what the slide is. Force is applied in equal measure on both.

Actual recoil in the Newtonian sense is only in play while the force is present. Once the force is removed…either by stopping the gas expansion or the the bullet exiting. Actual recoil is over so quickly that by the time our brains can process the fact that something has happened…it’s over…and what we perceive as recoil is actually momentum.

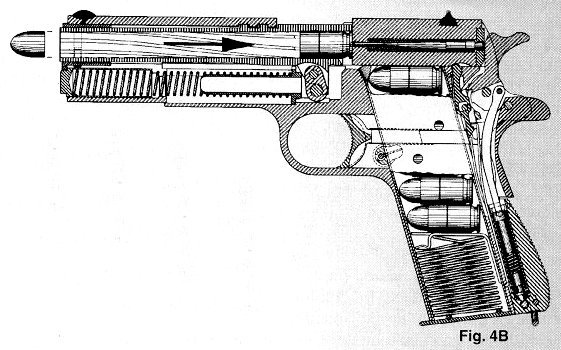

Recoil behaves differently in an autopistol than in a fixed breech arm, like a revolver or a bolt-action rifle. In the latter, recoil is immediately transferred to our hand or shoulder through the frame or receiver. With the autopistol, the recoiling part…the slide…is only connected to the frame through springs. In truth, the “gun” is the slide and barrel assembly. The frame is essentially no more than a gun mount…and the “gun” moves on rails.

Hypothetically, you could build a pistol with 30-foot frame rails, and mount the slide on the end with no spring connection…fire the gun…and feel nothing in the way of recoil unless the slide reached the impact abutment.

What we perceive as recoil is mostly muzzle flip, and that happens when the slide impacts the frame. By the time the slide hits the frame, the bullet is about 20 yards downrange.

The recoil system is a separate closed system. When the slide starts to accelerate rearward, the spring becomes a force vector, and sets in motion an action/reaction event that is separate from the ballistic event occurring in the “gun” assembly. As the slide compresses the spring, the spring pushes forward on the slide…and backward on the frame.

The stiffer the spring, the harder it pushes on the frame. While the stiffer spring does buffer the impact slightly, the sharper transference provided by the spring more than makes up for it. This can be easily demonstrated by firing a 5-inch gun first with a 14-pound spring, and then with a 20-pound spring. Simply put, the stiffer the spring, the more “solid” the connection between gun and mount.

We simply don’t need to overspring the gun, regardless of the hype. If the gun is properly set up, it will run just fine with a 12-pound spring.

But waitadamnminnit, Toon. Why do short variants have stronger springs? Isn’t that done to reduce the greater impact by the lighter, faster slides?

Nope. Assuming equal spring rates, the less massive Commander slide doesn’t hit the frame any harder than the 5-inch slide does. It’s moving faster..but it’s moving under the same momentum as the more massive 5-inch slide. If a stronger spring is used….it doesn’t hit as hard. Since the GM and Commander frames are essentially the same, aside from shorter rails and dust covers…and relocated impact abutments…the frame suffers no more than that of the Government Model class even with identical spring rates.

How can that be?

Simple physics. Bullet and slide momentums are theoretically the same. I say “Theoretically” because precisely equal momentums only occur in the absence of outside force, or in the presence of equal outside force. Because no normal gun can operate with equal outside force…the momentums can’t be exactly equal…but they’re so close that they can be assumed equal for the purposes of this discussion.

The less massive Commander slide is moving faster with a given cartridge…but because momentum is a function of Mass X Velocity…the momentum at the time of impact is therefore identical. Commander felt recoil is sharper than the 5-inch gun because a higher spring rate is typically used. Use the same spring rate, and the felt recoil will be virtually indistinguishable.

Then why the heavier springs in Commanders?

Again…The answer lies in understanding that the autopistol’s function is all about self-loading and returning to battery. It’s not so much about firing the shot as it is about the pistol readying itself for the next shot.

In order to do that successfully, the slide must feed and chamber the next round. Because that function is identical between the two pistols, the force required to overcome the resistance is the same…therefore the momentum in the slide must be up to the task. Because the slide’s mass is lower, it must be driven faster to generate the needed momentum to drive it to battery.

The other problem with the Commander is that the slide travel is shorter than the 5-inch gun’s, and the runup…the distance between the rearward limit and the magazine…is also shorter, giving the slide less time and distance to gain speed and momentum, so the spring has to accelerate the slide at a higher rate in order to compensate for both its mass and its shortened runup.

Which bring us to that plastic gadget…the ubiquitous shock buffer. That silly little thing is the “Pet Rock” of the 1911 industry. Another example of Snake Oil Marketing.

“If you don’t have this in your gun, you’re destroying the frame! You NEED this!”

It would be hard to estimate how much money has changed hands since the shock buffer burst upon the scene some 30 years ago. Pure genius. I wish I’d thought of it.

What many fail to consider is that the shock buff negates the rebound effect…the bounce…of the slide impacting the frame, which gives the slide a boost and makes the spring’s job a little easier and less critical in providing enough acceleration to return the slide to battery.

There’s just no such thing as a free lunch. The main problem with the 1911 today is that so many people have been trying for so many years to prove that they know more than Browning and his engineering Dream Team…that they really believe they have.

Over a hundred years ago, a man who is arguably the premier firearms design genius of the last two centuries and a team of very smart guys burned a lot of midnight oil in determining the proper spring rates for that pistol. They really did know what they were doing.

the shock buff has many applications for fucking up the gun. the fall apart and clog up the works after a short period of time. And they also often times make it hard if not almost impossible to eject loaded ammo, especially depending on the profile of the bullet

John, It’s awesome having you write for Range Bot, You are the most knowledgeable person I know concerning the 1911 platform. Looking forward to future articles by you!

[…] Go read this article… […]

The 1911 has worked just fine since, let me think…, 1911! Don’t screw it up with “farkles”!

Thanks for the article Hunter! I not very sure about the 1911’s, I have seen videos where they were shot without recoil springs. However in some of the other recoil operated guns, the actual impulse of different ammo, makes use of different recoil spring rates a useful and measurable option. Lower impulse needing less and higher impulse need more spring to help control the slide velocities. In my measurements on some they showed an increase in the amount of pull to pull the slide from in battery lock up and the actual spring rate at full rearward travel at the lock open positions. I like the non captive springs in my Glock guns for that extra spring rate at lockup…

It can be a delicate balance to where the recoil drives the slide fully rearward and allow the next cartridge to pop up, before the slide is returned forward to chamber it into battery.

Hi there, would it be advantageous to swap out the factory 16-18# springs with 14#ers ??

I recently did so in a new DW Specialist. I had some time on mu hands so I slow speed video’d it with Rem 230g FMJ’s There was improved dwell time at ejection over the 18# spring. The slide definitely did not hang open at ejection nor did slide slam or ricochet off itself while returning to battery… “Good Engineering” practices would say she’s good to go.. but not being educated on this is why I ask if I did alright by doing this spring swap..

Thanks,

Cliff